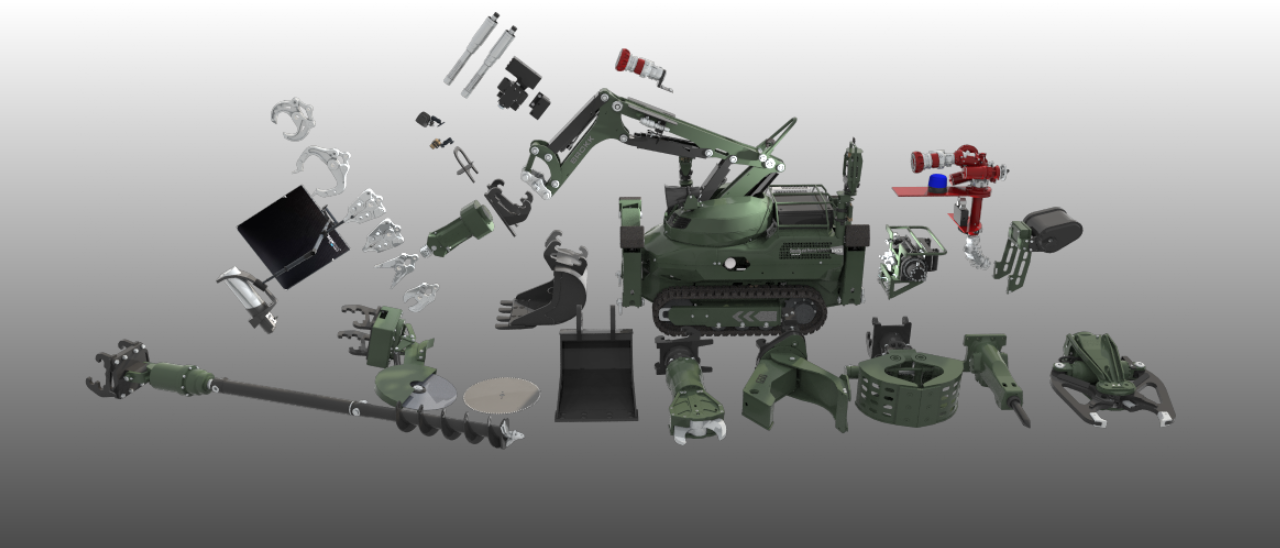

Attachments

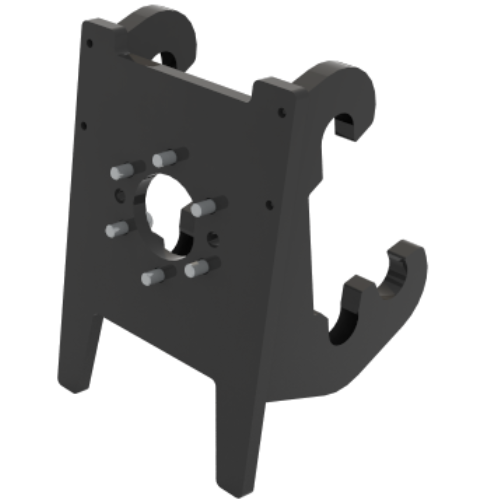

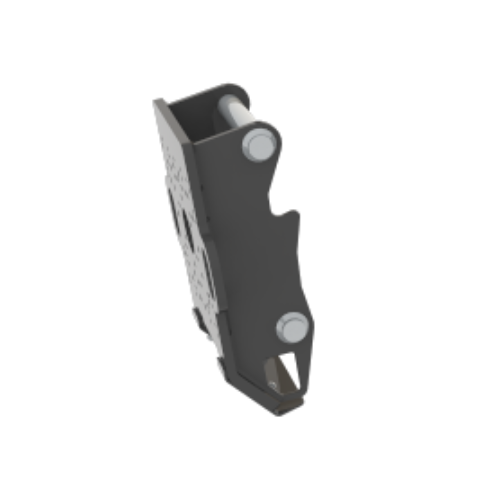

| MX/MD/MN-120/520/800 | TMP-M – Tool Mounting Plate Manual

Tools attached to the robot arm main tool interface must ether support the Brokk Patented Quick Hitch, or if not, they require an TMP-M. The TMP-M have a weight from approximately 20kg and upwards, depending on robot and the tool to mount. This weight and the weight of the tool is often mentioned in this document when this weight effects the practical manipulating capacity of the robot. TMP-Manual for MX/MD/MN120 Approximately 20 kg, TMP-Manual for MX/MD/MN520 Approximately 75 kg, TMP-Manual for MX/MD/MN800 Approximately 120 kg |

|

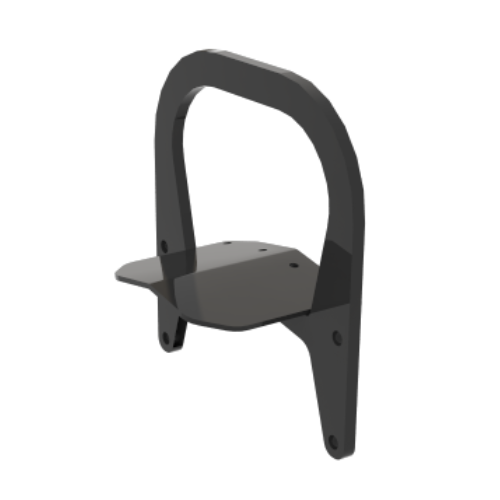

| MX/MD-120/520/800 | MPM – Mount and Protection Module

The OPTIONAL Mount and Protection Module for the TMP give a fixed mounting as close as possible, and with an as good as possible angle to the tool and give extra protection to the sensor and LED Light. The additional weight is most often negligible. |

|

| MX/MD-120/520/800 | TSM – Tool Sensor Module

The TSM include the high performance tactical EO-Sensor (camera) and a LED Light. The TSM is included in the MX and MD Series as standard. This Module have a fixed position in the MPM, but can also be positioned and re-positioned on any metal surface on the outer part of the arm, with the included magnets, to give optimal view depending on tool. |

|

|

||

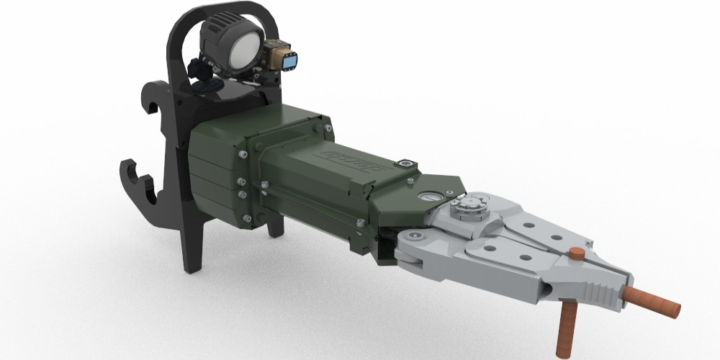

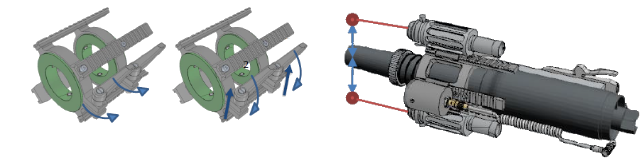

| MX/MD/MN-120/520/800 | TMP-R – Tool Mounting Plate Remote

If the robot is equipped with the Integrated Remote Tool Change (IRTC) or Integrated Remote Tool Change with Tilt and Rotation (IRTC-TR) as the main tool interface, all tools must support this standards or be equipped with a TMP-Remote. The TMP-Remote connect not only mechanically, but also the oil and com/electric couplings. |

|

|

||

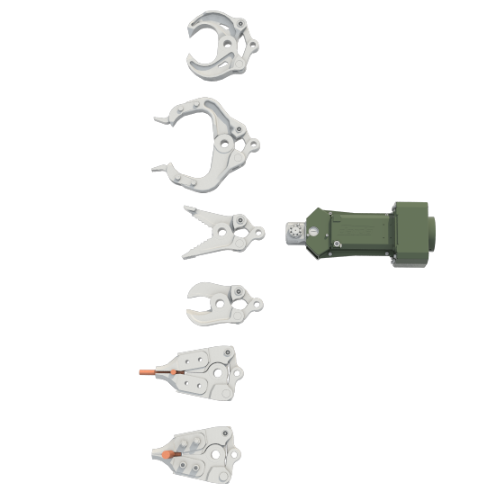

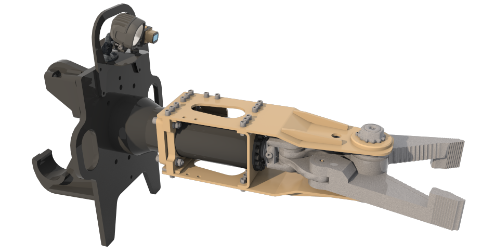

| MX/MD/MN-120 | Multitool HCS8 SV20-C

The recommends standard/multi tool for the MX/MD/MN120 is the HCS8 SV20 with exchangeable jaws. The HCS8 SV20 is in standard supplied with rotation and the C-jaw, that is a multitool made for cutting, picking and spreading. |

|

| MX/MD/MN-120 | Multitool HCS8 SV30-C

If the power of the HCS8 SV20 is not enough, we offer the HCS8 with a booster package (SV30) increasing the weight and length, but also the power of the tool. Other features and jaws are the same as the SV20 above. |

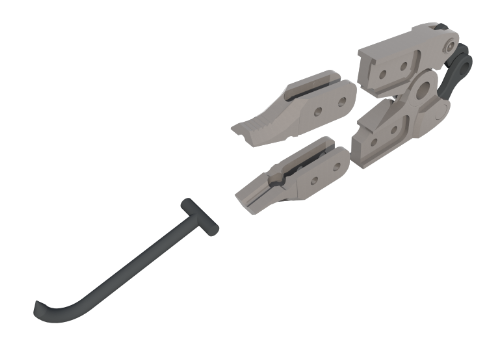

| MX/MD/MN-120 | Exchangeable jaws for the HCS8 SV20 and HCS8 SV30

The different standard jaws for the HCS8 SV20 and SV30 can be changed by an operator in matter of minutes and the new jaw can facilitate the specific operations significantly. |

|

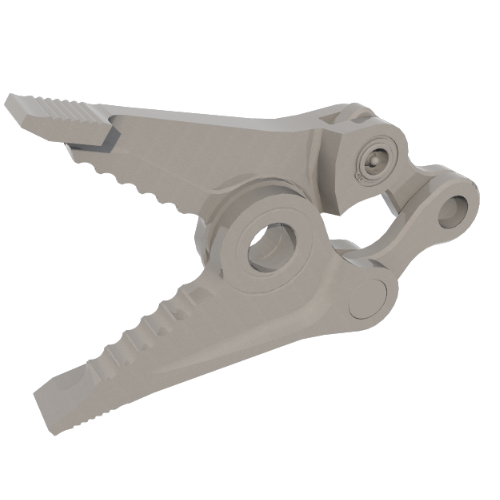

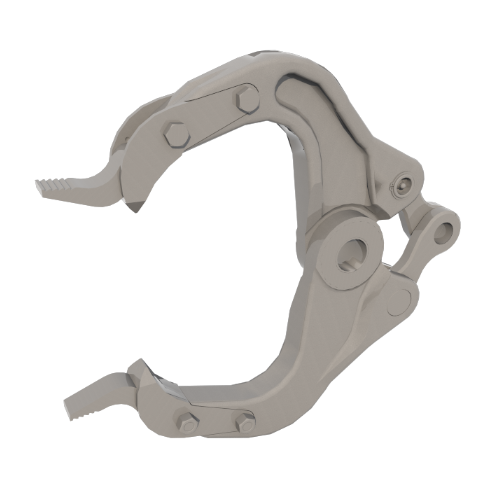

| C-Jaw

The C-Jaw is normally standard included in the delivery of the HCS8-SV20 /SV30 and has a maximum opening of 256mm, tip to tip.) The C-jaw is a multi jaw to be used for e.g. manipulate, cutting and spreading/opening e.g. doors. |

|

|

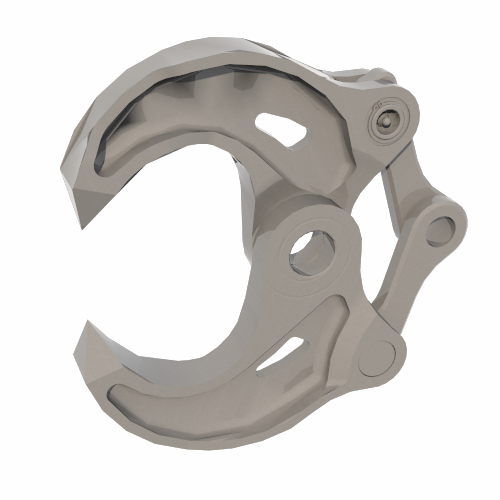

| B-Jaw

The B-Jaw facilitates the manipulation of larger objects. The B-Jaw has a maximum opening of 330mm. However, if you flip out the upper and lower foldable flap/part of the B-Jaw, you can also use the tool for spreading. Maximum spreading would be 448mm. The B-Jaw can also be used for crushing of softer material such as a brick wall. |

|

|

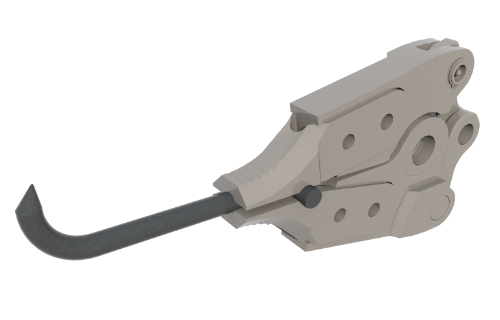

| J-Jaw

The J-Jaw was made for crushing concrete but can also be used for manipulating objects. The maximum opening of the J-Jaw is 172mm. |

|

|

| S-Jaw

The S-Jaw was made for cutting and is a good tool for e.g. opening up a car, such as cutting hinges or even A or B pillars of the car. The design of the S-Jaw utilizes the force from the HCS6SV20 or 30 in a maximum way, giving impressive result for a tool this light and small. |

|

|

| Multi Jaw with exchangeable inserts

The Multi jaw can be equipped with standard or tailored inserts, that are changed by loosening 4 screws. The T-30 and T-20 inserts are made more for manipulating in general, but in particular to be complemented by your own or BSRS made tools using the “T-grove” inside the insert. |

|

|

| The T-30 insert

with a T-Grove of 30mm diameter and a maximum opening of 329mm. |

|

|

| The T-20 insert

with a T-Grove of 20mm diameter and a maximum opening of 329mm. |

|

|

| The P insert

is mainly for picking and placing |

||

| Special design,

on request |

|

|

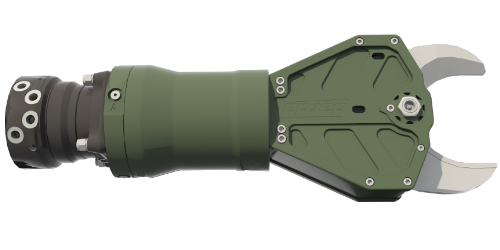

| MX/MD/MN-120/520 | Multitool HCS7 SV03 (C or S)

The recommended standard/multi tool for the MX/MD-120/520 is the HCS7 SV03 with exchangeable jaws. The HCS7 SV03 is in standard supplied with rotation and either C-jaw, that is a multitool made for cutting, picking and spreading, or S-Jaw, that is more tailored for pure cutting. (Picture also include TMP-M, MPM and TCM) |

|

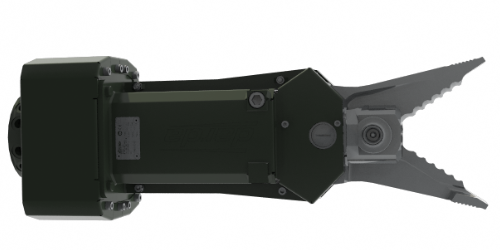

| MX/MD/MN-120/520/800 | Cutting tool MC200 and MC300

For additional cutting power, the MC200 and MC300 are available to facilitate even the most difficult cutting tasks. (Picture also include rotation) |

|

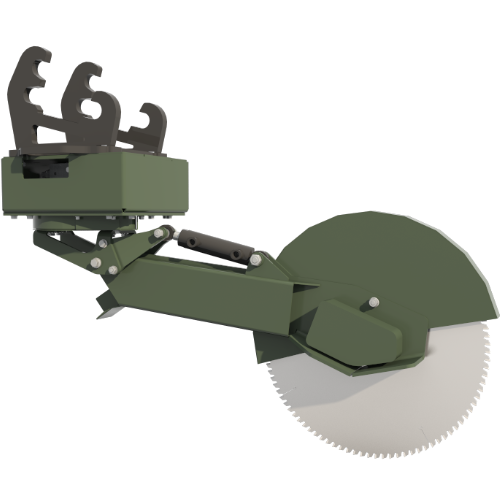

| MX/MD/MN-120/520/800 | Cut-off saw

The suggested cut-off saws are developed by Brokk to give a fast and efficient alternative to shearing. The cut-off saws leave a very clean cut without distorting and twisting that can be the case with the cutting tools. The saws can be delivered with different disks depending on your needs, also disks giving very little or no sparks. (Picture also include TMP-M) |

|

| The saw is equipped with a separate side angling to give further access angles. BCS65 and BCS90 are also available with optional water flushing for cutting concrete. BCS65 and BCS90 can also be equipped with saw disc size 800mm, 1,000mm and the below 1,200mm. BCS15 with 400 mm or 600mm disc and a torque of up to 27Nm. | ||

| MX/MD/MN-120/520/800 | Buckets

A standard range of buckets for digging, but that can also be used for removal of dangerous items where, to some extent, the bucket itself protects in some directions (depending on use and angle) from blast wave and smaller/lower velocity fragments. (Bucket with TMP-M) |

|

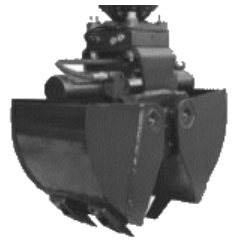

| MX/MD/MN-120/520/800 | Clamshell

A standard range of clamshell buckets for digging, but that can also be used for removal of dangerous items where, to some extent, the clamshell bucket itself protects in a horizontal direction from blast wave and smaller/lower velocity fragments. The Clamshell can also be equipped with continues rotation. |

|

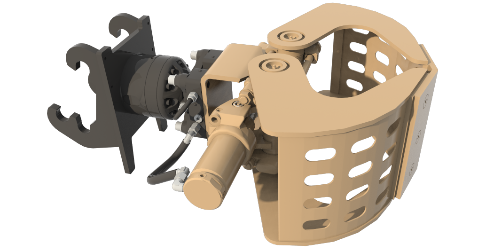

| MX/MD/MN-120/520/800 | Sorting and Picking Grapples

The suggested Sorting and Picking Grapples are equipped with continues rotation. The models are balanced between capacity and weight and can be used or large to smaller objects, and some even suitable for simpler digging. |

(Picture also include TMP-M and rotation) |

(Picture also include TMP-M and rotation) |

| MX/MD/MN-120/520/800 | Multi-Purpose Grapples

The suggested Multi-Purpose Grapples are equipped with continues rotation. The models are balanced between capacity and weight and can be used for large to smaller objects, and even suitable for simpler digging. |

|

(Picture also include rotation) (Picture also include rotation) |

(Picture also include rotation) |

|

| MX/MD/MN-120/520/800 | Drum Cutters

The standard Drum Cutter is designed for trenching, demolition and concrete surfaces. (Picture also include TMP-M) |

|

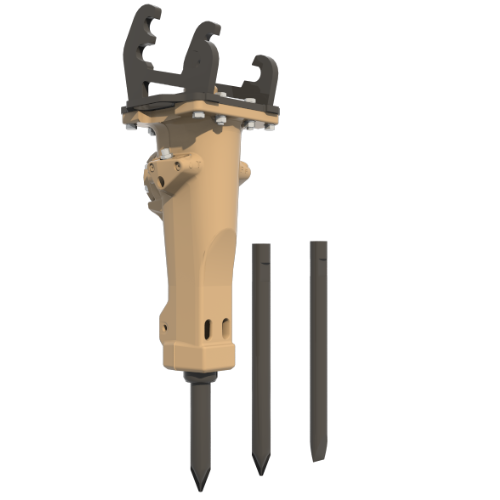

| MX/MD/MN-120/520/800 | Breakers

The robot system can obviously also be equipped with the breakers. The breakers can all be equipped with a wide range of different chisels. Pls NOTE Care should be taken when use in combination with various optional sensors. This when the breakers create significant vibrations to the arm but also the robot body in general. (Picture also include TMP-M) |

|

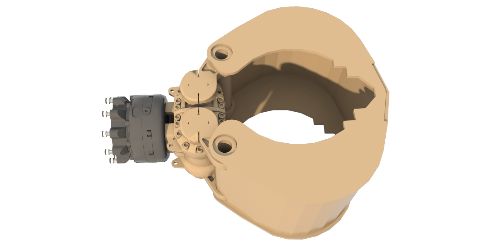

| MX/MD/MN-120/520/800 | Crushers

Powerful standard concrete crushers that are recommended for the robots are the CC340 and the CC700. The crushers are all supplied with continuous rotation, exchangeable tips and there is a separate blade for cutting rebars in any reinforced concrete. (Picture also include TMP-M) |

|

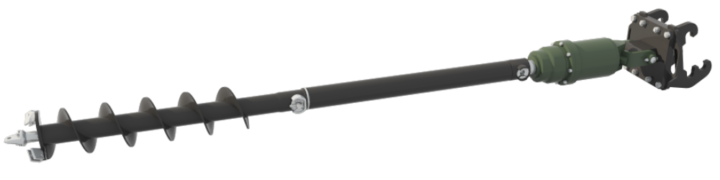

| MX/MD/MN-120/520/800 | EDM – Earth Drill Module (see also OPTION EDM-Earth Drill Module)

The EDM is hydraulic and is quickly attached to the main tool interface. The EDM need a TMP-M or TMP-R with a Link Block. The Earth Drill is connected to the Link Block. The Link Block comes in two versions. The Cardan Link, allowing the drill to move in four directions in relation to the TMP during drilling. The second is also Cardan Link, but also with a fixed back-support allowing also horizontal drilling. EDM Earth Drills The standard earth drills come, depending on EDM, in diameters from 100mm to 1,500 mm. They can be ordered with tailored teeth for either Earth, Tungsten or Rock. EDM Fixed Drill Extensions S4 roundS4 Ext-E 500mm – S4 Ext-E 800mm – S4 Ext-E 1,000mmS5 squareS5 Ext-E 1,000mm – S5 Ext-E 1,500mm – S5 Ext-E 2,000mmS6 squareS6 Ext-E 1,500mm – S6 Ext-E 2,000mm – S6 Ext-E 2,500mm – S6 Ext-E 3,000mm |

|

|

||

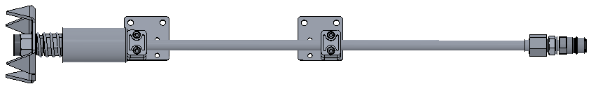

| MX/MD/MN-120/520/800 | HWM – Hydraulic Winch Module

The HWM is a powerful hydraulic winch alternative for your SRS-robots. The module can be connected/disconnected in roughly 20-30 minutes. |

|

|

||

| MX/MD-120/520/800 | FMM – Firefighting Monitor Module

The Firefighting module consists of a remotely operated monitor, fitted and integrated with the robot in a way making it easy to connect and disconnect depending on the needs for the specific mission. The Module is placed at the back of the robot and can be used to fight fire around the robot while for example making its way into a building using a breach tool. Its position also ensures water is cooling down the machine while working in hot environments. If more cooling is needed it is possible to change the spray pattern into a mist. |

|

| MX/MD-120/520/800 | FFM – Firefighting Fixed Module

The Firefighting Fixed Module consists of a remotely operated spray nozzle fitted to the robot on arm section two. The aim of the water is achieved by operating the turret and arm of the robot. On/Off and spray-pattern are remote controlled giving more flexibility but can limited access to the arm for other operations. |

|

|

| MX/MD/MN-120/520/800 | FFM-UHP Firefighting Fixed Module – Ultra-High-Pressure and Water Cutting

The FFM-UHP is a highly efficient firefighting tool that only requires a low volume of water. Other uses are water cutting when used with added in abrasives. The size and speed of the water droplets increase the cooling surface of the water volume exponentially, a very efficient way to cool down a fire. |

|

|

||

| MX/MD-120/520/800 | WCM – Weapon Carrier Module (pending Export Licence)

The WCM features calibratable aiming reticles, laser range finder and powerful LED light which are interfaced with the SRS-Systems OCM. The system can carry two Vulkan Maxi De Armer Disrupters and a Benelli M4 Super 90 Shotgun or alternatively Benelli M3 Tactical Shotgun. The WCM is attached/detached to the tailored WCM interface in minutes using two pins and the Communication/Power connector. |

|

| Firing circuits for the disrupters and trigger actuation of the shotgun is achieved by use of a separate Radio Firing System, e.g. the below optional BAM Approved, 4 channel RF firing system. However, the end user can utilise their existing in-service RF initiation system if available |  |

|

| The basic WCM include:

The Maxi ROV Weapon Carrier is mounted directly onto a quick release side plate mounted on the SRS-Systems arm three (3), to give good manoeuvrability and aiming, still keep the WCM away from other tools mounted on the SRS-Systems main tool interface, up to a width of approximately 460mm without blocking the disrupter (MX120). (see OPTIONS WCM for details) |

|

|

|

|

|

WCM OPTIONS:

|

|

|

| MX/MD-120/520/800 | DCM – Disrupter Carrier Module

The DCM is an alternative to the “full-size” weapon carrier for 0.5m to 30m shots. It is a mechanical holder or frame for disrupters like the Chemring RE70/RE50 and Richmond Defence Vulkan/Viper, but with various inserts the holder can be modified to house other brands. The DCM consists of a frame with three NATO Accessory Rail systems, where two can be used for mounting Chemring lasers, the third can be used for an additional camera when needed. One of the Chemring lasers is a bore site and aiming laser, the other is just an aiming laser for close up water shots. The DSM can be used without lasers or additional cameras by simply holding the DSM/disrupter with the gripper of the robot as close as possible to the object and using the tool camera to aim. The DSM needs the additional/external firing system but can be powered from the robot. |

|

|

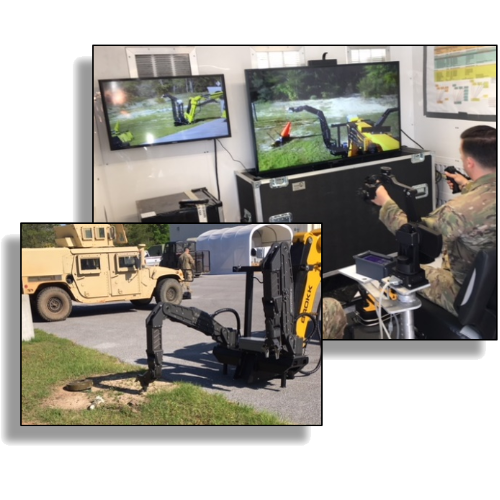

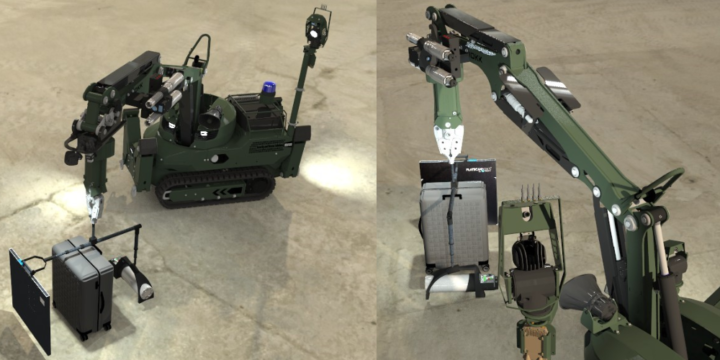

| MX/MD-120/520/800 | FAM2000 – Force-feedback Arm Module 2000

The FAM2000 is a 7-function hydraulically powered robotic manipulator for delicate and intuitive work, while still offering a reach of over 2m and a lifting capacity of more than 90 kg (200 lbs) at full stretch. The arm is mounted on the standard tool interface of the MX/MD-Series but is controlled with a separate master/slave arm with force-feedback at the OCM. |

|

| For an even more human like operation two arms can be combined. (Pls note that such combination may need the 520 or 800 platform.) | ||

| MX/MD-120/520/800 | XRM – XRay Module

The basic X-Ray30XS consists of the flatscan 30XS and CP160B source. The system is in basic configuration mounted in a frame that can be adjusted manually to fit the object in question, prior to deployment. The basic frame is designed to fit with the T-grip of the HCS8 Multi Jaw T-30 Insert but can be modified to fit also other standard tools. |

|

| The robot carries the complete module to the object of concern, where it can be placed or hold in a position for optimal image. The module can also be rotated to give the operator further angles for easies evaluation of the images. (see also OPTION XRay30XS Module Basic) | ||

|

||

| MX/MD-120/520/800 | AWC-L Abrasive Water Cutting Module Large

The AWC-L is a complete powerful water cutting system. However, the system may need modifications in terms of gripping and interface depending on the specific use. This can be from a standard T-30 grip, where the cutting is performed using the HCS8 functions to perform the cut. All the way to automatic/semi-automatic systems where the robot act as carrier and holder of the device. The main components of the system are: |

|

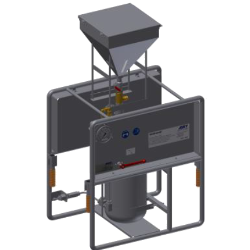

| AWC remote mixing module:

700bar, empty weight approximately 130 kg (725x500x780mm), 14 kg abrasive capacity (gives approximately 20minutes of cutting) |

|

|

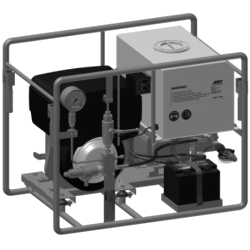

| AWC remote pressure module:

700bar, empty weight approximately 150 kg (900x580x710mm), 50 l water tank and a waterflow of 6 l/m. |

|

|

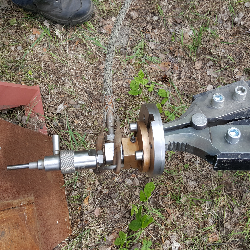

| AWC cutting nozzle

D 0.6mm and 700bar, DN 6, 10 m high pressure hose. (picture only example) |

|

|

| OPTIONAL

but highly recommended AWC-Service Set incl. a selection of spare parts and tools for corrective and preventive maintenance packed in “Peli type” box. |

||