System Integration

| MX/MD-120/520/800 | RTM – Remote Trolley Modules

The RTM is a modular trolley concept that can be connected, and disconnected, to/from the robot remotely. The RTM can be configurated to serve as everything from a sophisticated relay station that can be connected to e.g. the SOC in the TMC via optical fibre and thereby extend and/or make the connection even more reliable, alternatively serve as a tool carrier and everything in between. The RTM is pulled behind the robot to the area of operation, where it remotely can be disconnected /connected. |

|

|

||

| MX/MD/MN-120 | BCT-2000 – Basic Covered Trailer (see also OPTION BCT)

The BCT is a trailer with a maximum total weight of 2.000kg, loading capacity maximum 1.540 kg. Loading volume approximately L3m x W1,5m x H1,6m. The BCT is equipped with fasting points to fixate the MX/MD/MN-120 during transport. The trailer is equipped with a towing bar with a ball connection to the car or van of 50mm diameter and an electrical 13 pin connector (13 to 7 pin adaptor is included). The trailer is covered, with balanced tip function and with a loading ramp. |

|

|

| MX/MD/MN-120 | BCT-X3500 – Basic Covered Trailer eXtended (see also OPTION BCT)

The BCT-X3500-1 is a two-axel trailer with a maximum total weight of 3.500kg (maximum loading 2.650 kg. Loading volume approximately L3,6m x W1,5m x H2,1m. The BCT-X3500-1 is equipped with a tow-bar that is possible to adjust in height and can be equipped with different towing devices for e.g. “ball” and hook. This configuration makes it possible to alter the towing vehicle from e.g. van to truck. The BCT-X3500 is equipped with fasting points to fixate the robot during transport. The trailer is equipped with LED Light, 9-36V, powered by the towing vehicle. |

| MX/MD/MN-120 | The BCT-X3500-2 is further equipped with a hydraulic, manual pump, system used to lower and angle the trailer for loading and unloading the robot. This reduces the loading angle and facilitate loading/unloading. Maximum loading capacity 2.400kg. The back of the trailer is divided into two parts. Upper part protects against rain when opened, the lower serves as loading ramp. |

| MX/MD/MN-120 | The BCT-X3500-3 is further equipped with a hydraulic, automatic electric, system. Maximum loading capacity 2.350kg. |

|

|

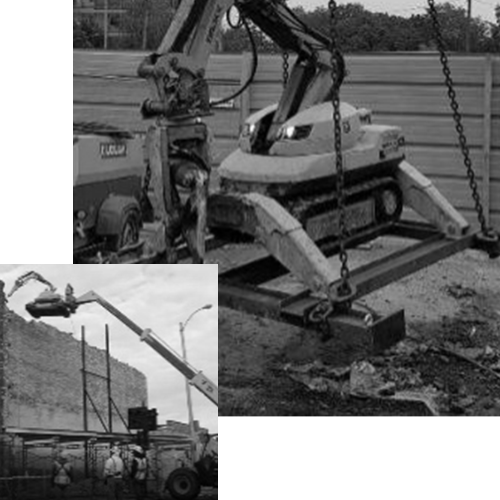

| MX/MD/MN-120 | FLP – Forklift (crane) Lifting Platform

Is a steel frame with two fork tunnels for forklift/telescope handler and lifting eyelets for crane, or similar, lifting. The MX/MD/MN120 is secured and locked down into the frame for secure and remote work from height. |

|

| MX/MD/MN-120/520/800 | HFC – Hooklift Flatbed Carrier

Maximum design weight of 24 tons, 7m long and compatible with standard Hooklift trucks. The HFC gives both space and loading capacity for the MX/MD/MN800 with various options. In standard including 2x loading ramps of 800mm length. Paint in accordance with specification RAL colour.(see also OPTION TSC-TMC-SOC) |

|

|

| HFC-C – Hooklift Flatbed Carrier – Covered

The Covered flatbed carrier is purpose built to facilitate transport of the MX/MD/MN800, but can obviously be used for other systems also. In contrary to the HFC, the HFC-C is covered by heavy duty tarpaulin to give good weather and “visual” protection during transport and storage. To facilitate loading of the system, as well as any other OPTIONS, the HFC-C is equipped with a rolling system to uncover the sides and a roll-up system at the back. Inner length of 6.5m, outer 6.7m. The outer width is set to 2.6m, not to exceed European road transport regulations. Paint in accordance with specification RAL colour.(see also OPTION TSC-TMC-SOC) |

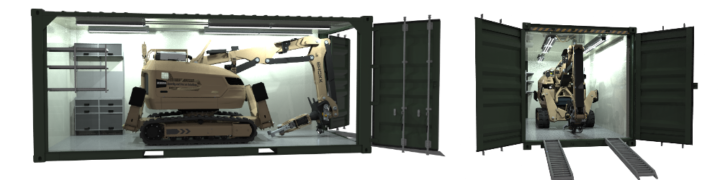

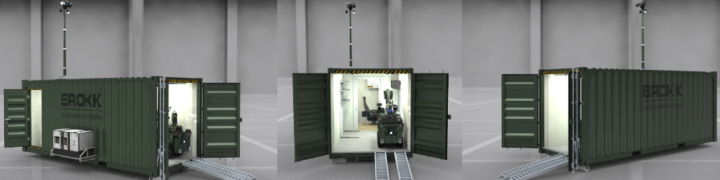

| MX/MD/MN-120/520 | TSC-10 and TSC-20 Transport and Storage Container

The TSC-10 is a 10 ft container for pure transport and storage of one MX/MD/MN-120. TSC-20 can store and transport several MX/MD/MN120 or one MX/MD/MN520.(see also OPTION TSC-TMC-SOC) |

|

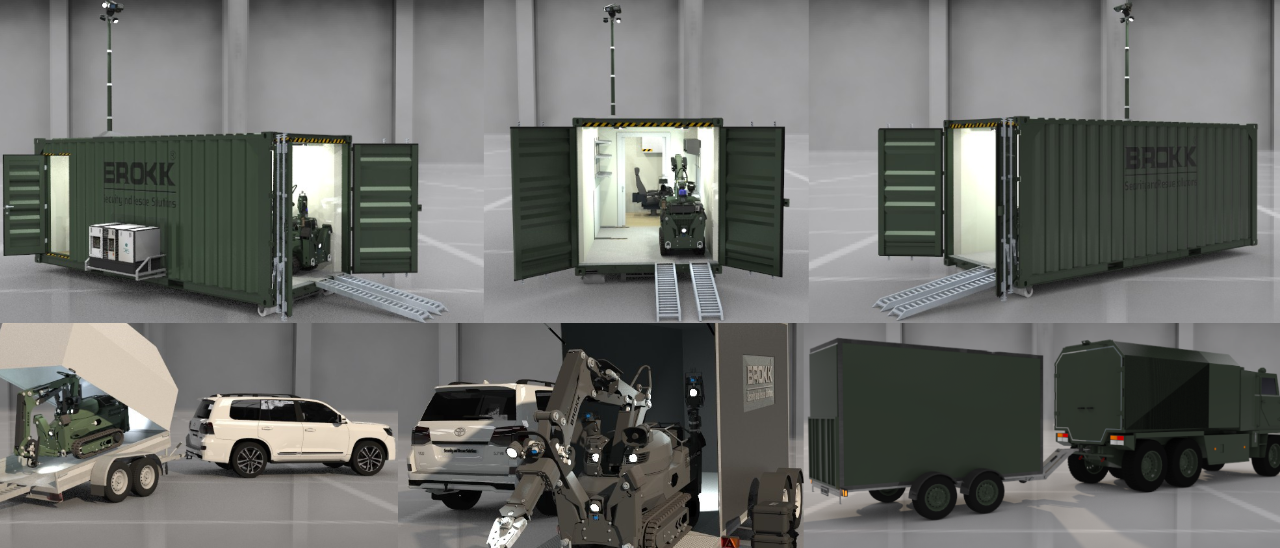

| MX/MD/MN-120/520 | TMC – Transport and Maintenance Container

The TMCs are standard (ISO 668) 1C/1A, 1CC/1AA or HC/1AA (High Cube) containers for various use with the BSRS robotic systems. The basic container is insulated and with electrical heating as well as a class 4 locking system. There are 10 fastening points for robots and the container is equipped with storage and maintenance modules, that can be used for e.g. spare parts and tools suitable for maintaining the robot system. The container is also equipped with LED lights and 230VAC sockets, but the system needs external electricity supply. |

|

|

|

|

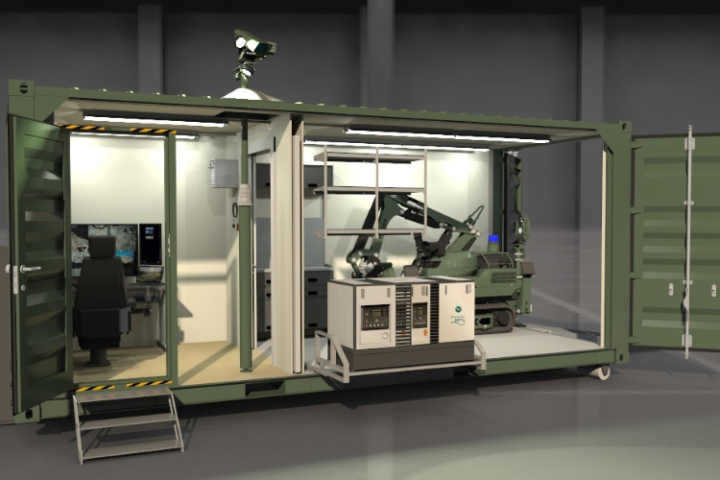

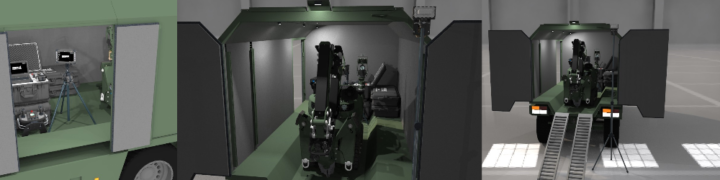

| MX/MD/MN-120/520 | TMC-SOC-20 and TMC-SOC-4

The TMC-SOC´s are in basic configuration equipped as the TMC, but further divided into two rooms, where the larger is for Storage and Maintenance and the smaller to serve as Stationary Operator Control room. The SOC-Room can be equipped with standardized and tailored equipment to support the remote operations with the BSRS robotic system. Such are e.g. racks with larger screens and an operator chair with integrated joysticks and controls for optimal overview and comfort/ergonomics. The system is also equipped with the integrated and erectable antenna mast TRM-X-A.(see also OPTION TSC-TMC-SOC) |

| MX-120/520 | SOC – Stationary Operator Control

The SOC consists of several modules and can be used for stationary operator control in e.g. a car, van, truck or container. The system can be tailored by use of different standard and tailored modules. Any prices given should be considered indicative, when the final configuration may affect the cost. Final configuration is determined in dialog with the customer. Examples:

The above are only examples of the standard range. BSRS can also supply the system with the vehicle, such as the Mercedes Sprinter. If BSRS supply the whole system, further standard and tailored systems for facilitating operation can be integrated. Systems such as generator, air-condition, vehicle modules for tools and general storage, etc.(see also OPTION TSC-TMC-SOC) |

|

|

|

|

||

| MX/MD/MN-120/520/800 | Vehicle and Special Integration

Due to the modular design, our standard operator modules can be used for most temporary or more stationary integration with different vehicles or in any other space for operation. However, we can also assist in modifying for even more optimal fit. |

|

|

||