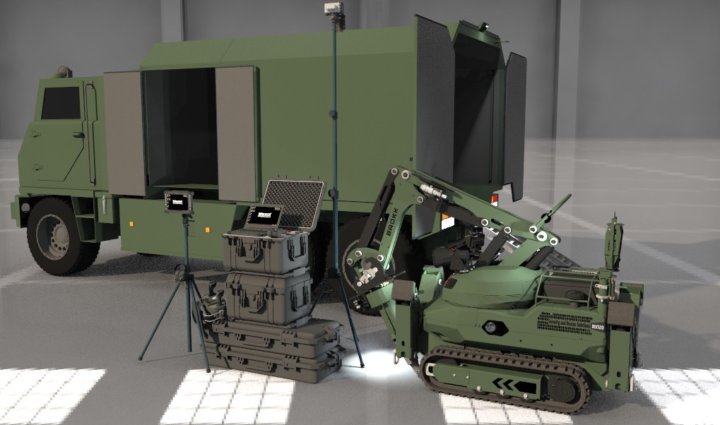

Operator Modules

MX-Series – Flexible Operator Modules

The brain of the system is the Operator Control Module (OCM). In essence the standard mobile OCM consists of a robust case with integrated power and control. The main screen is a rugged laptop where most sensor information is displayed and controlled. E.g. the real-time video.

There are two basic video modes to choose from, either drive or manipulate mode. Both of them show a split screen with all five cameras, in drive mode the two drive cameras are enlarged, where as in manipulate mode these are made smaller and the tool camera is enlarged. The operator can also choose to open and expand one camera to get a full-screen mode and to be able to zoom in on suspected parts on the screen.

The OCM also houses the joystick to control the two pan/tilt camera modules, battery status display and a separate colour “mini” screen that displays and controls the platform data and control the LED-lights individually. The OCM is supplied with one pair of MIL-Std robust and high quality headphones with microphone.

|

The OCM – Operator Control Module “the brain” Feeds the operator information from multiple sensors Modular design for total control and flexibility Easy setup |

|

After video quality, new users are often most impressed with the Remote Control Module (RCM). Extensive Brokk history with millions of operator hours has produced a robust RCM with an ergonomic design ready for many hours of operation. However it is often the intuitive control in operating the robot that amazes operators. For LoS operation most users may only need a couple of minutes of introduction before they can operate themselves, for NLoS operation most need more training.

The RCM includes the same type of colour mini screen as in the OCM so the same functions can be monitored and controlled here also.

|

The RCM – Remote Control Module “the arms and fingers” Intuitive control Proportional control system gives: Speed and highest power To sensitive and delicate manipulation |

|

Last but not least the Transmitting/Receiving Module (TRM).

The basic TRM includes the radio module and a telescopic antenna mast that can be erected to a maximum height of 3m. The TRM is connected to the OCM by a 15m cable. This basic setup was chosen to give the operator the possibility to position (and reposition) the TRM in the open for maximum reception, while the operator stays protected indoor, vehicle, behind a wall or any other protection.

We also supply an OPTIONAL TRM, the TRM-X. The TRM-X also consists of a telescopic mast but can be erected to 5m high. This module theoretically supports LoS communication at a distance doubling (x2) the specified for the basic system. However the most important aspects from a practical point of view is the flexibility to work in even more difficult NLoS missions.

Another very important feature of the TRM-X is the integrated camera with pan/tilt function that is linked to the directional antenna at the top of the mast. With the zoom function of the camera, the operator can get a very good overview of the area of operation, and depending on terrain, keep an overview during the whole operation. Your own “eye in the sky”. (an Automatic version of the TRM-X, the TRM-X-A, is supplied as option to our SOCs Stationary Operator Controls.)

|

The TRM – Transmitting/Receiving Module “the nervous system” connecting your fingers, eyes and ears to the robot more than 1.000m away (LoS) |

|

Operator Options |

||

|

|

|

|

|

|

Data-Link and Sensors |